3D Printed Tooling Supports Prototype Foam Seating

3D printed tools could be a faster, more affordable way to prototype and produce foam parts for automakers and other OEMs.

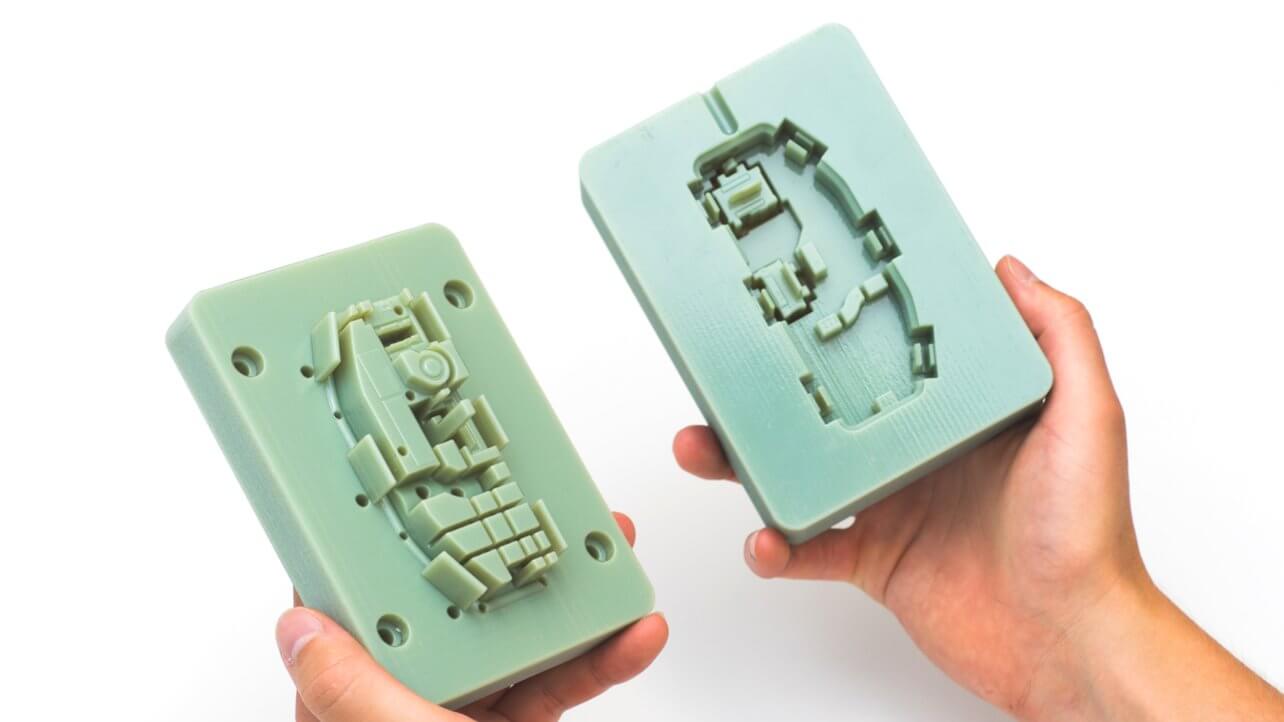

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

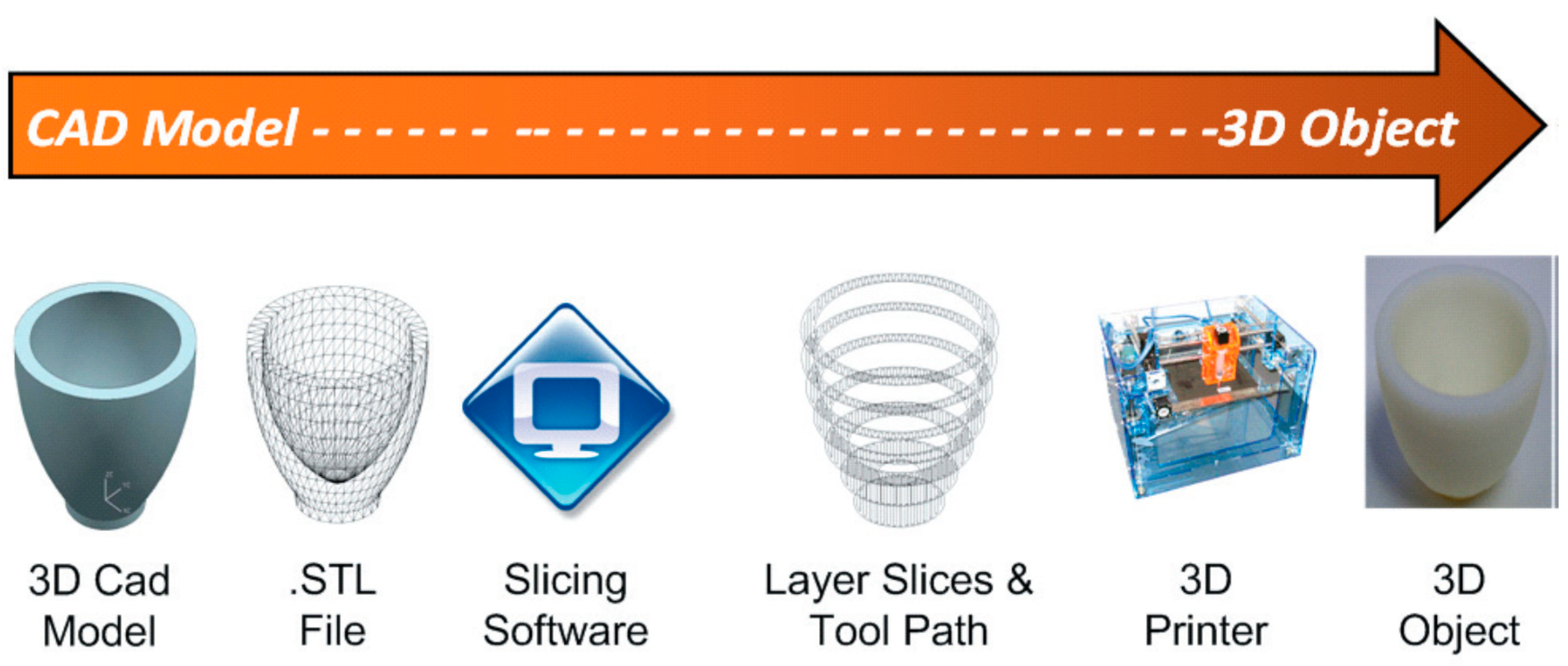

How 3D printed tooling can shape the future of prototyping

Desktop Metal introduces FreeFoam photopolymer resins

ExOne Acquires Freshmade 3D Assets

Development and evaluation of a facile mesh-to-surface tool for customised wheelchair cushions, 3D Printing in Medicine

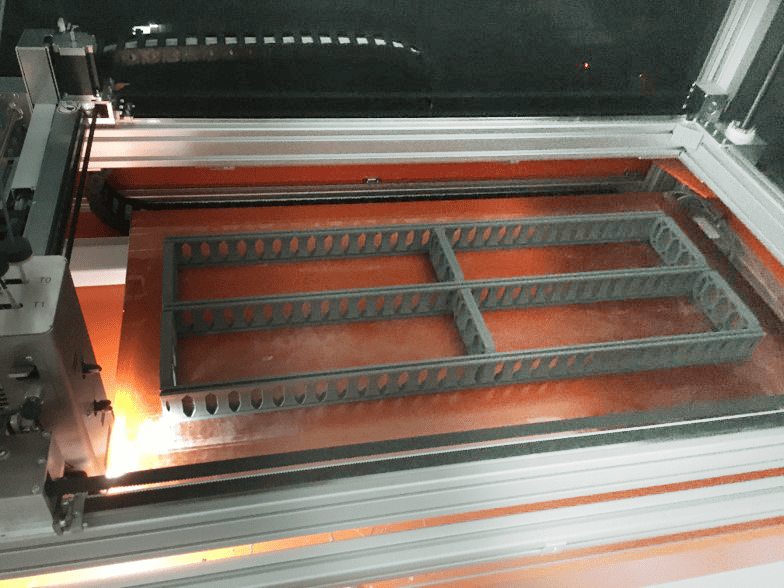

BigRep Industrial 3D Printers

Making life more comfortable for wheelchair-using individuals with a 3D- printed medical-grade cushion

Home - Catalysis Additive Tooling

ExOne Acquires Freshmade 3D Assets

Darrell Stafford on LinkedIn: Big 3D printed tools.

3D Printed Tooling Supports Prototype Foam Seating

Top 10 3D printed products designed to make sustainability a part of your everyday life - Yanko Design

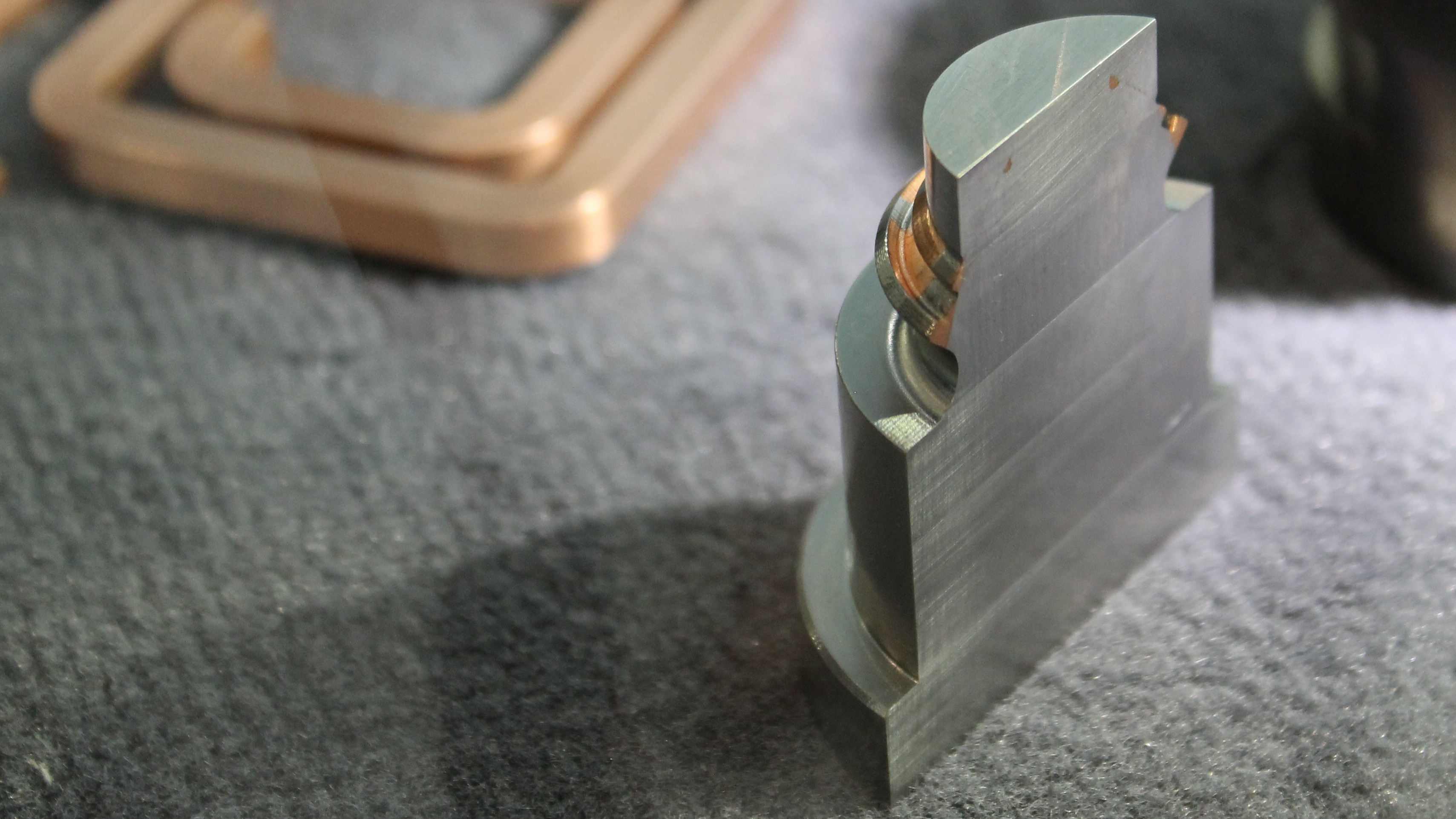

Hermle Combines Metal Powder Application Process with Five-Axis

Polymers, Free Full-Text

3D Printing in Automotive

3D Printing at the Turn of Iten's Century