Table 1 from Burr Dimension Analysis on Various Materials for Convenantionally and CNC Drilled Holes

PDF) Optimization of drilling parameters of epoxy/rice husk composite material

Table 1 from Burr Dimension Analysis on Various Materials for Convenantionally and CNC Drilled Holes

Cutting Forces in Drilling Operation: Measurement and Modeling for Medium-scale Manufacturing Firms

Modification and analysis on fatigue study in universal joint of an automobile vehicle - ScienceDirect

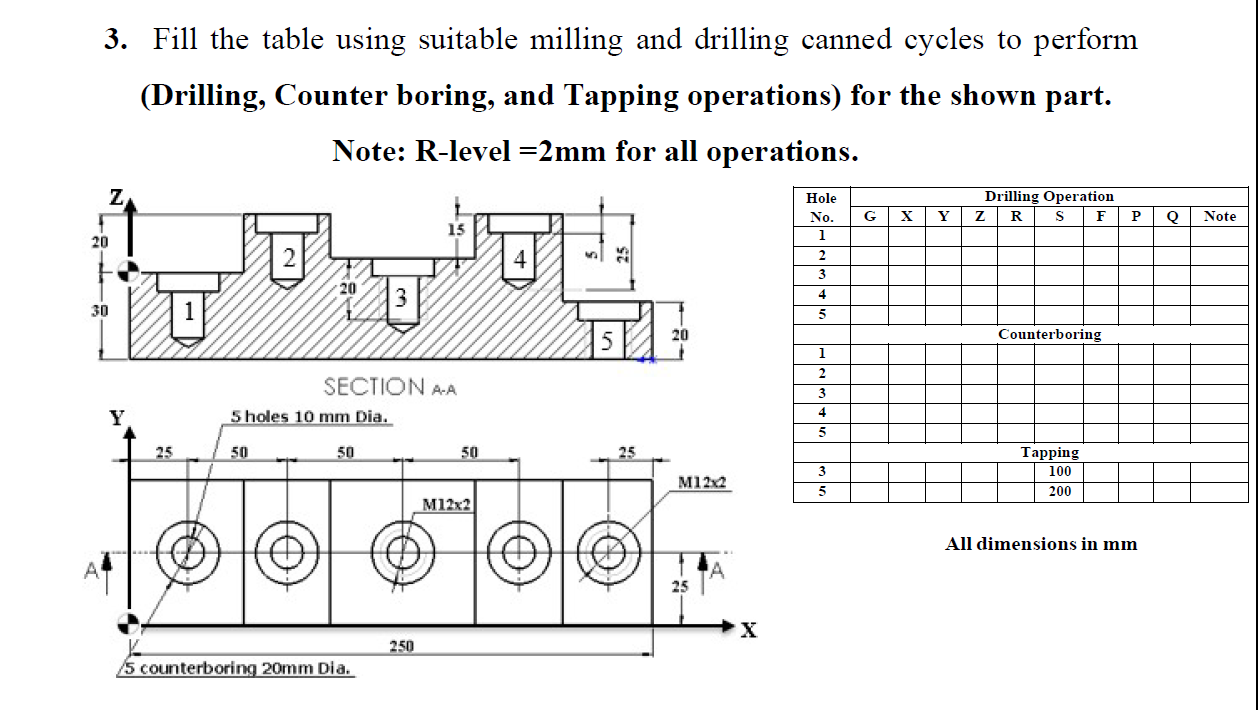

Solved 3. Fill the table using suitable milling and drilling

Analysis of burr formation in finish machining of nickel-based superalloy with worn tools using micro-scale in-situ techniques - ScienceDirect

Table 1 from Burr Dimension Analysis on Various Materials for Convenantionally and CNC Drilled Holes

The static structural analysis of torque converter material for better performance by changing the stator angle - ScienceDirect

Hole quality in terms of burr formation in multi-spindle drilling of

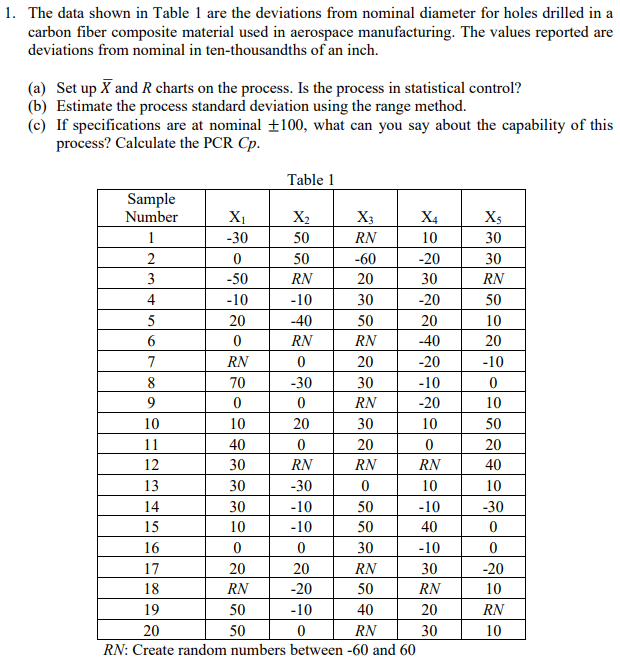

1. The data shown in Table 1 are the deviations from

Forests, Free Full-Text

Analysis of burr formation in finish machining of nickel-based superalloy with worn tools using micro-scale in-situ techniques - ScienceDirect

:max_bytes(150000):strip_icc()/metal-alloys-2340254_final-ca186a30b3454d7d936ad12114d6cdd9.png)