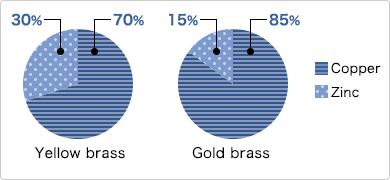

Chemical composition of the lead-free brass

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

The 13-node subparametric shell element.

Meridional stress distributions at steel bars for tanks T7, T8, and T9

GloBrass,ECO BRASS(Lead-free brass with excellent machinability

Chemical composition of the lead-free brass

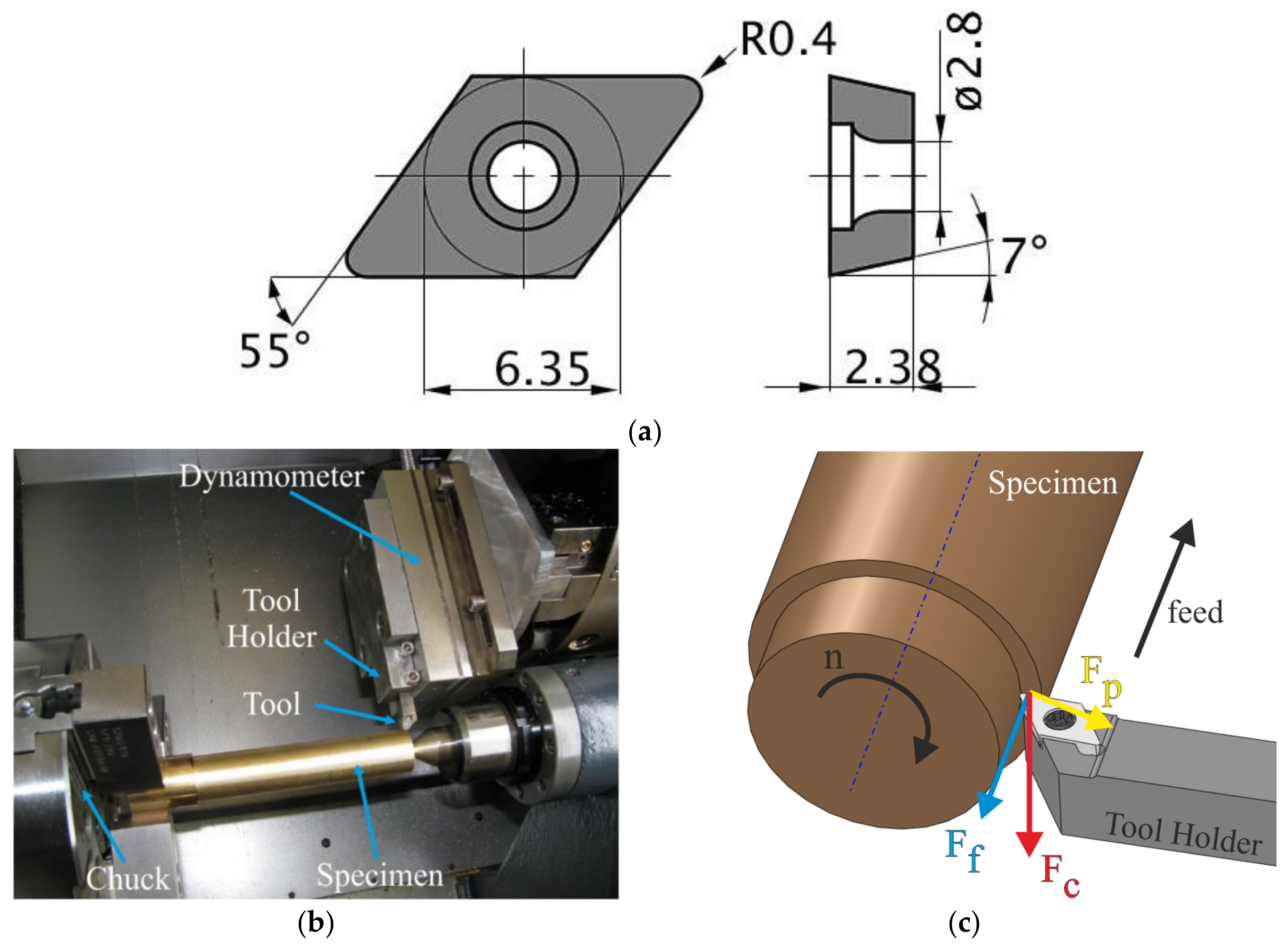

Metals, Free Full-Text

Reinforced concrete elevated conical tank located in China. Fig. 2.

Bending moment of the deck resulting from Case (1) and Case (2) under

On the function of lead (Pb) in machining brass alloys

All About Brass as a Manufacturing Material

Modified Johnson-Cook Flow Stress Model With Therm, PDF, Deformation (Engineering)

Bending moment of the deck resulting from Case (1) and Case (2) under

Lead Free Brass Rod, C69300 Eco Brass Rod, IS 4413, BS 2874