Plastic Injection Mold Base Functions and Structure - Parts of Mold

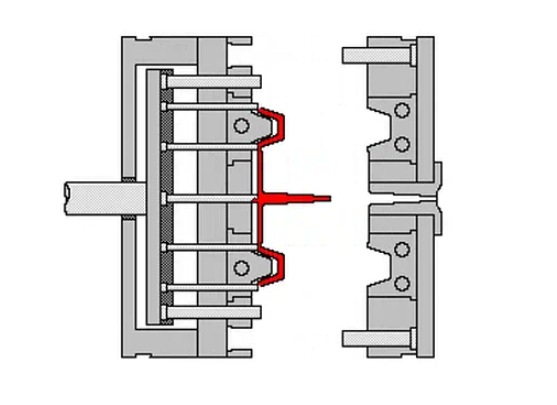

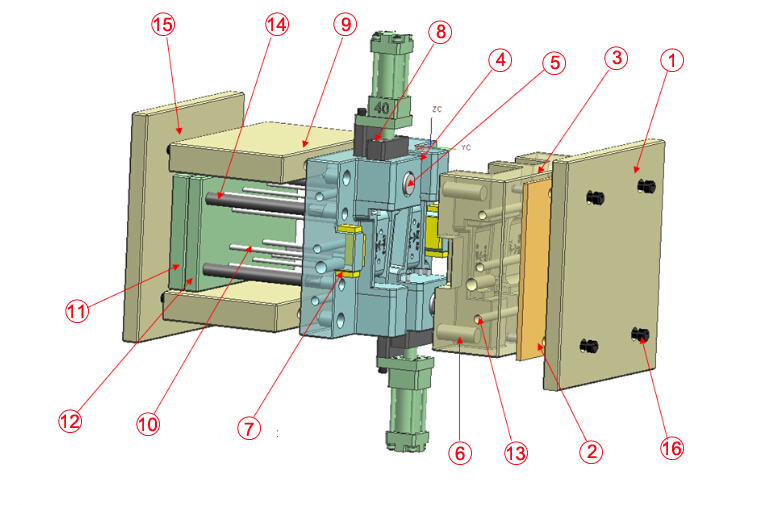

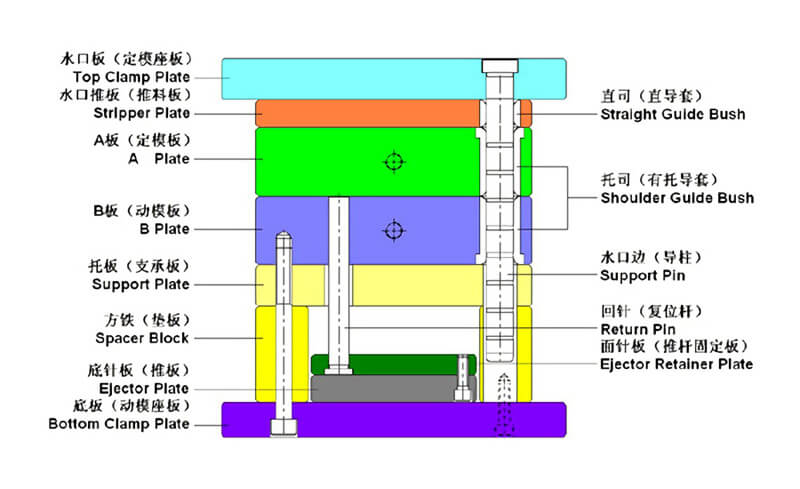

A plastic mold plate is any plate required to build a complete plastic mold, and all injection mold plates used for molds have the main requirements, they are : 1. Good corrosion resistant 2. Good Machinability. 3. Easy to clean 3. Good heat transfer. 4. Homogeneity of steel. 5. Easy ability. 6. Low Cost. at the picture below you can see 3 plate mold base type with closed position, basically, 3 plate type injection mold and 2 plate injection mold have some main plate structure, see explanation about plastic injection mold construction type to understand more, explanation plastic injection mold parts and function below based on the number at those 3 plate mould pictures: 1. Fixed Clamping Plate or Top Plate The fixed clamping plate or the top

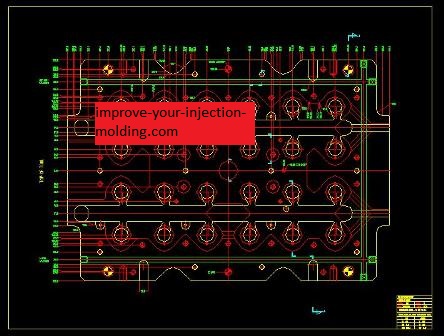

Schematic drawing of the mold for an injection molding process. The

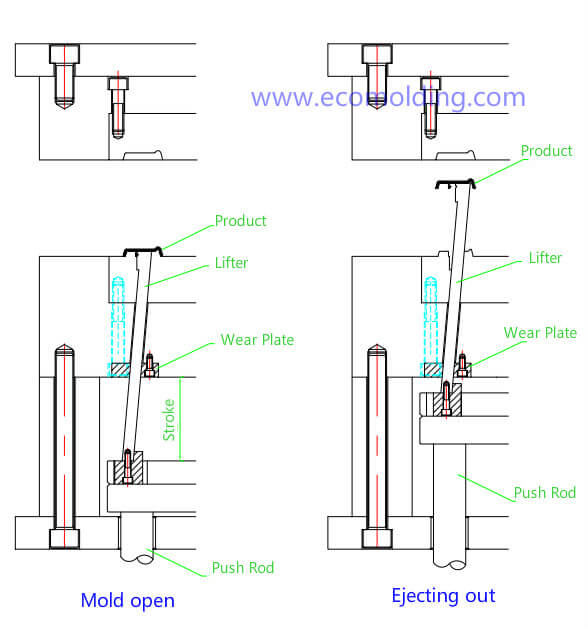

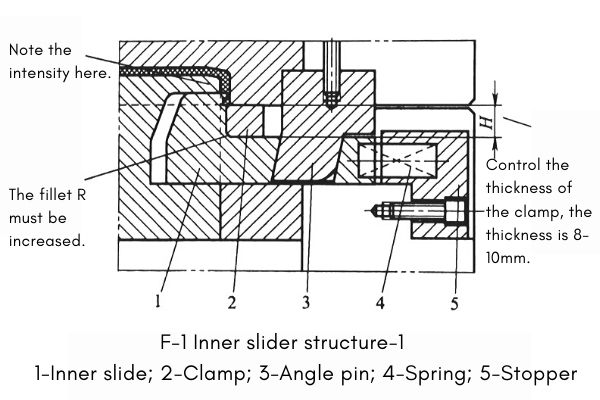

The lifter design standard for plastic injection mold tooling

Usual mold parts and their function

Injection mold structure design: 4 common mechanisms.

The types of Mold base for plastic injection mold

Difference between three-plate mold and two-plate mold

Mold Life Expectancy

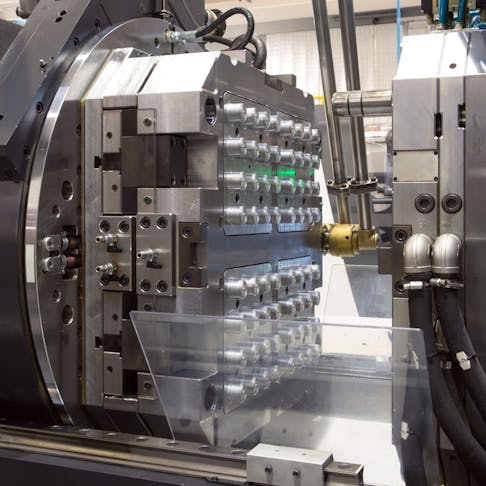

The outline of injection molding

What is the function of each part of the injection mold? - Quora

Components of an Injection Mold

elements of mould / component of mould / important part of mould

Structure diagram of an injection molding machine injection unit.

Plastic Injection Mold Base Functions and Structure - Parts of Mold