Activated Carbon Filter: Production and Function - primaklima – filtration, ventilation, metal forming

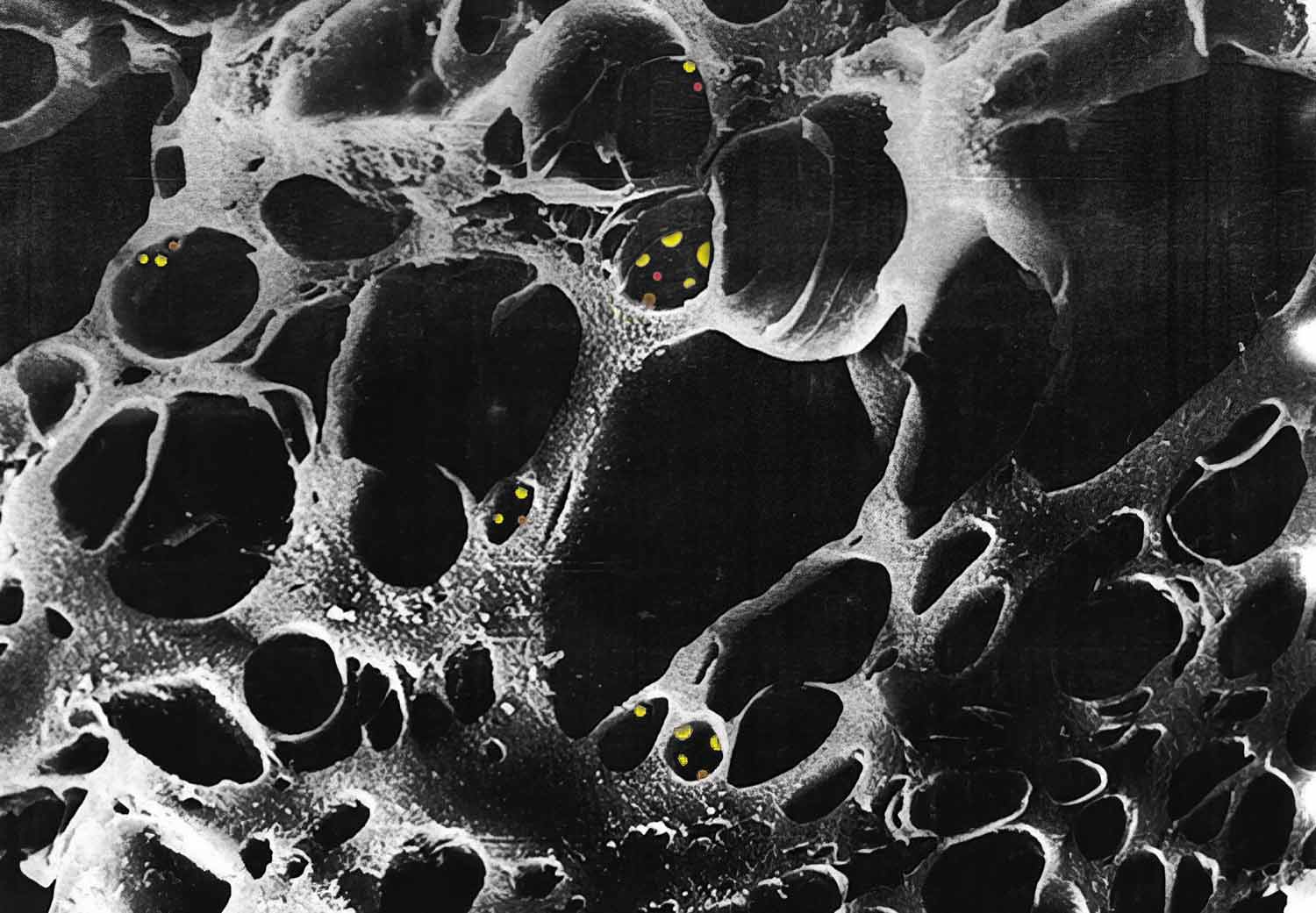

Activated carbon can be obtained from various materials such as black coal (anthracite), coconut shells, brown coal, and wood. For financial reasons, activated carbon is usually manufactured using the steam activation process. During this process, the raw material is activated by hot steam under vacuum in a furnace at a temperature of approximately 900 to 1100 °C. The absence of oxygen prevents the material from burning. Instead, the heat causes the internal surface of the material to increase significantly. Activated carbon produced in this way can then be further processed for various purposes.

næse balance Grisling coal filter squat Mig Bevægelig

New generation series- auto & manual carbon filter_21 Dec 2020.cdr

VIVOSUN 6 Inch Air Carbon Filter Smelliness Control with Australia

HYDROMAG-006-Hydroponics-Magazine by Hydro Magazine - Issuu

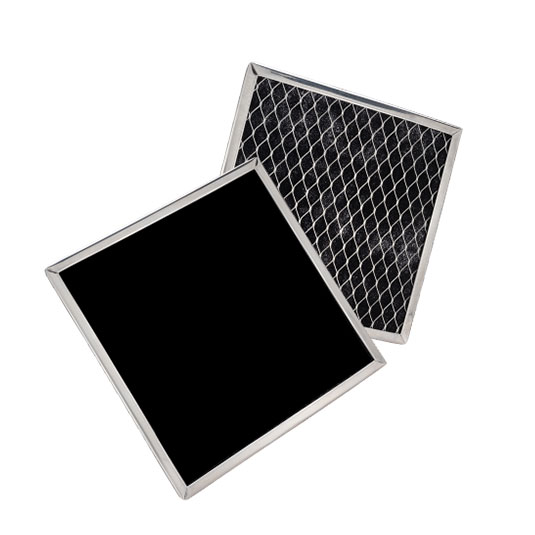

Activated Carbon Filter

Stainless Steel Pressure Sand Filters And Activated Carbon Filter at Rs 200000 in Mumbai

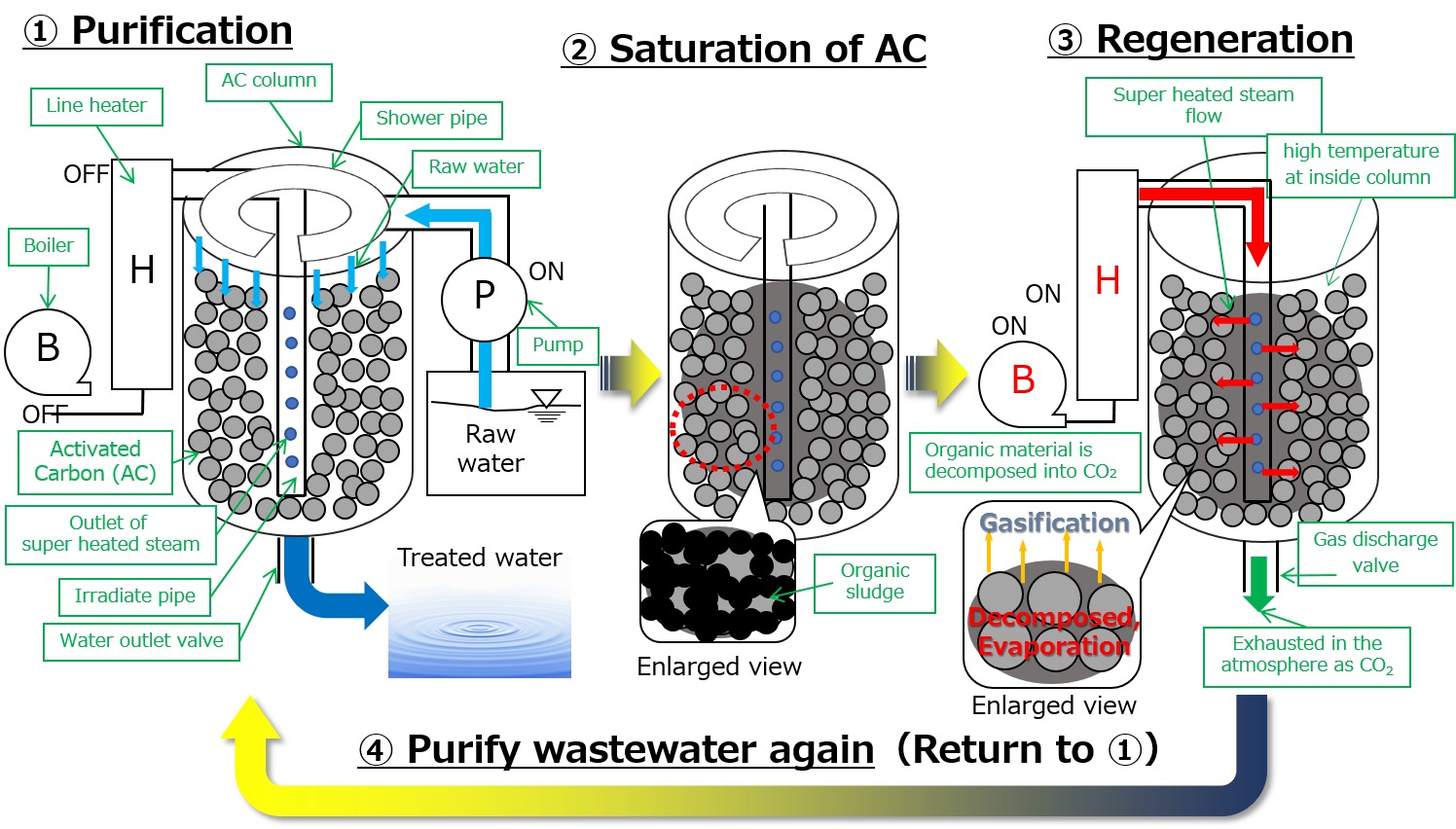

On-site Regeneration System of Activated Carbon Filtration Unit

næse balance Grisling coal filter squat Mig Bevægelig

næse balance Grisling coal filter squat Mig Bevægelig

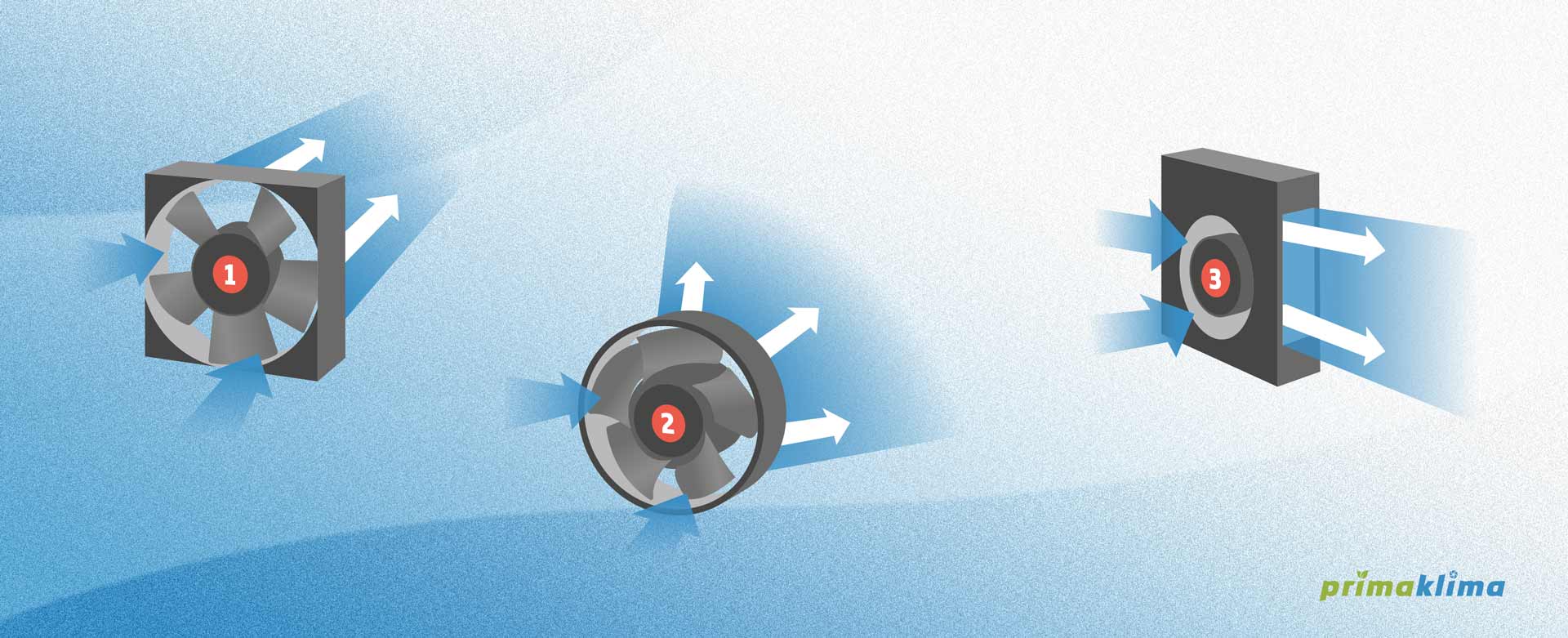

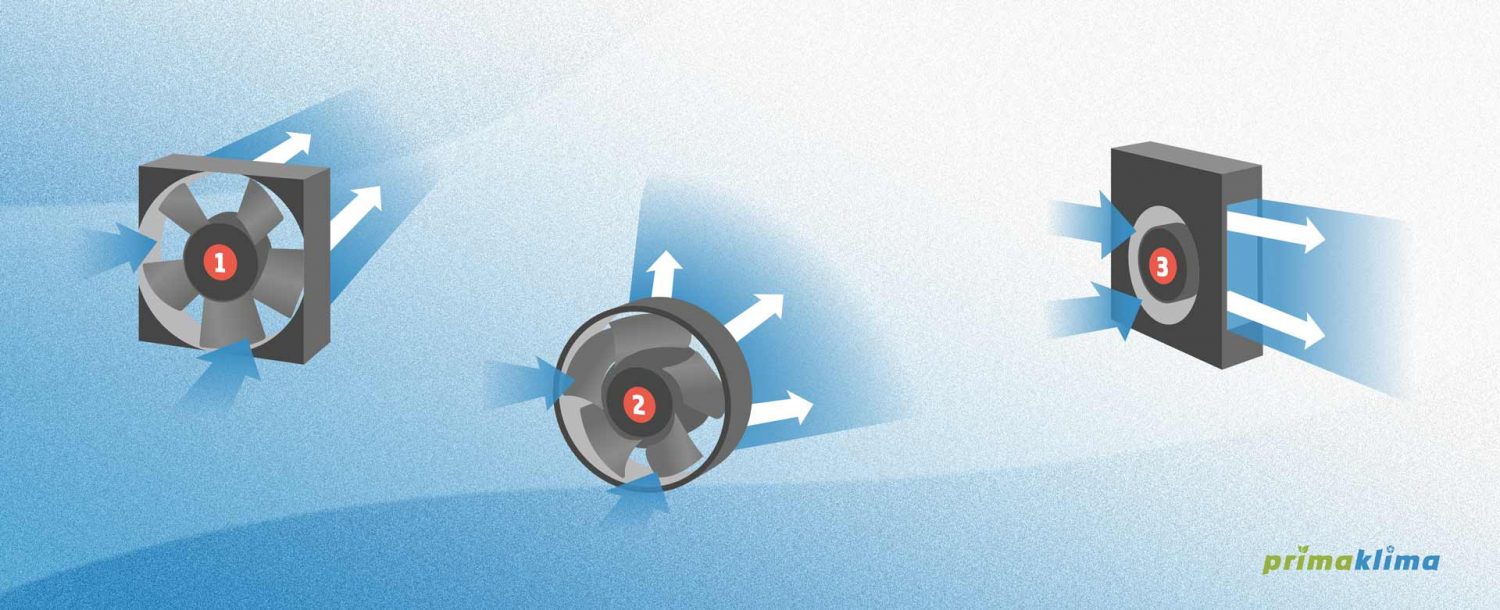

Ventilators: Construction and Functionality - primaklima – filtration, ventilation, metal forming

K1803 - 3 mm pellets, 2,5 kg of activated carbon - primaklima

Blog - primaklima – filtration, ventilation, metal forming

PrimaKlima Industry Line K1609 - 810/1090m³/h - Ø200mm

Carbocone - Activated Carbon Filters