Manufacturing process of a shackle consisting in jaw forming (a, b)

Download scientific diagram | Manufacturing process of a shackle consisting in jaw forming (a, b), body forming (c), and crown bending (d) [23] from publication: Investigation of the key process parameters in the hot forming of a shackle | To investigate the impact of the variations of different input parameters in the multi-stage hot forging process of a shackle, an analysis is carried out through numerical simulations of the whole manufacturing process. Due to the complexity of the process and the large | Forging, Manufacturing Systems and Hot Forging | ResearchGate, the professional network for scientists.

Manufacturing process of a shackle consisting in jaw forming (a, b)

pewag winner Chain system in G10 Lifting and Lashing by pewag - Issuu

Thermo-mechanical forming of a large sling shackle

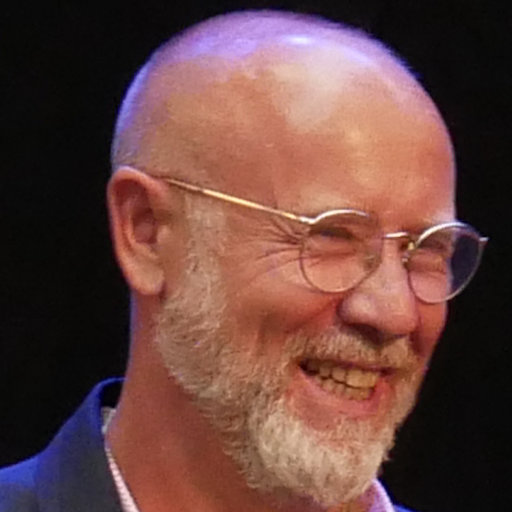

Sandrine THUILLIER, PhD, Université Bretagne Sud, Lorient, UBS, IRDL – Institut de Recherche Dupuy de Lôme

Crosby 'G209' Screw Pin Bow Shackles, WLL Range from 330kg to 55,000kg - LiftingSafety

Pierre Yves MANACH, Professor (Full), PhD, Université Bretagne Sud, Lorient, UBS, IRDL – Institut de Recherche Dupuy de Lôme

Resource management for sustainable intensive agriculture systems

RUD Lifting means system main

All-in-One End-Effector Design and Implementation for Robotic Dissection of Poultry Meat